Making a grand piano: 1. The inner and outer rim

The classic grand piano shape

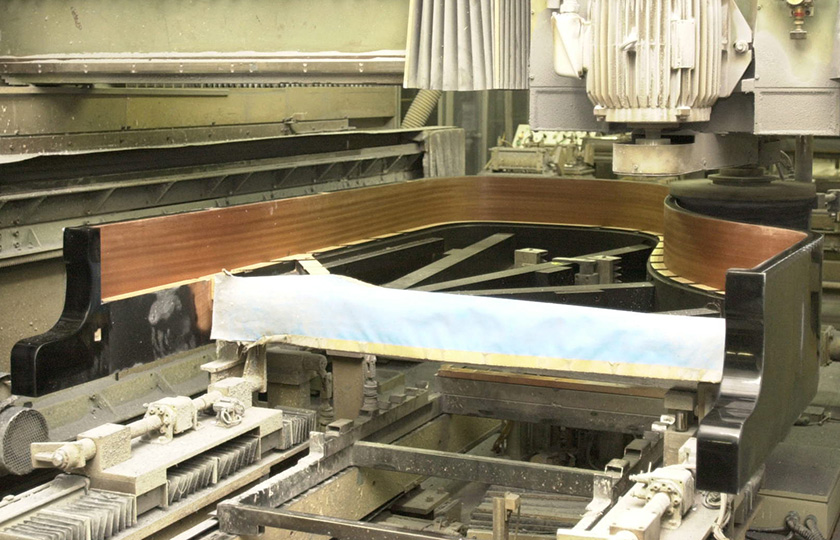

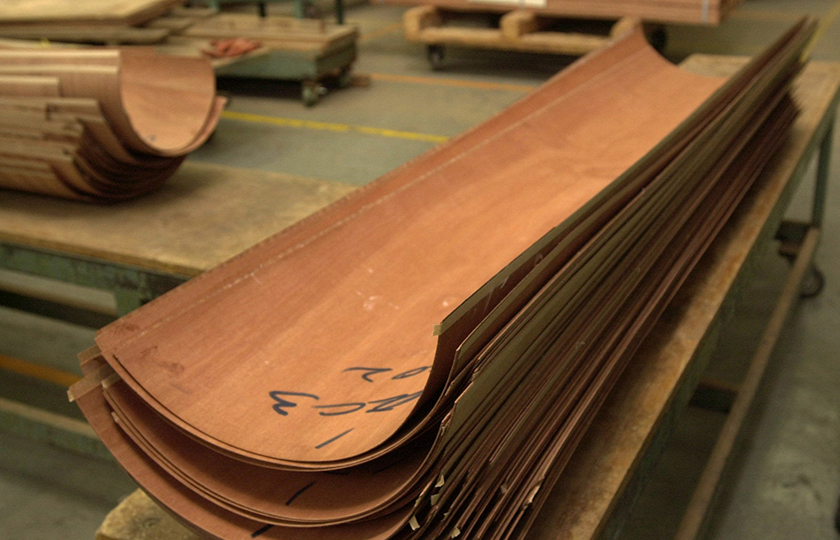

Layers of wood veneers are glued together with the grain in a uniform direction to form a long, flat piece of wood which will eventually become the outer rim of the piano. These layers are then joined to make a single long piece by being glued and laminated, which depending on the model can be made up of between 6 and 10 layers.

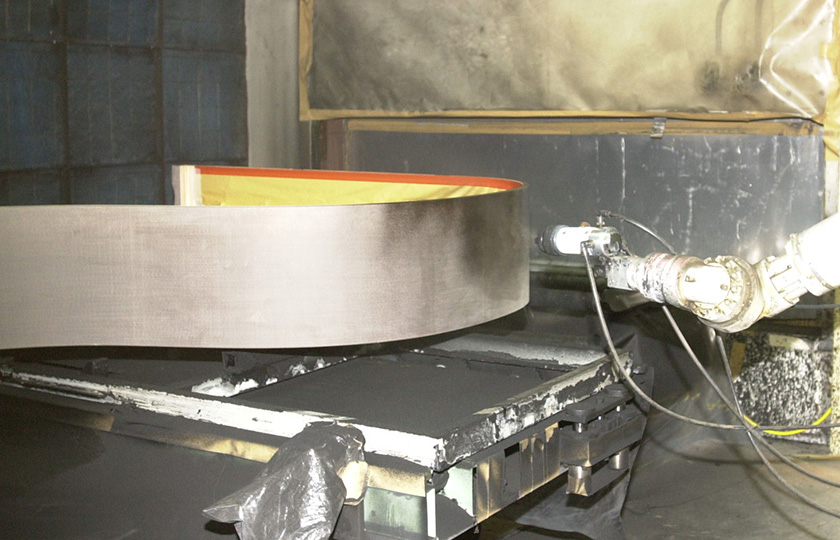

Once the long, laminated wooden board is made, it is placed in a press that uses high-frequency energy to heat the wood, and hydraulic pressure to press the board into a large mould that has the distinctive shape of the piano case. Resin-impregnated paper is then glued to the outside of the rim to provide a receptive surface for the finish to be applied.

Pianos which are destined to have a wood grain finish have very thin wood veneers glued to the outside of the rim.

The Inner rim of the piano:

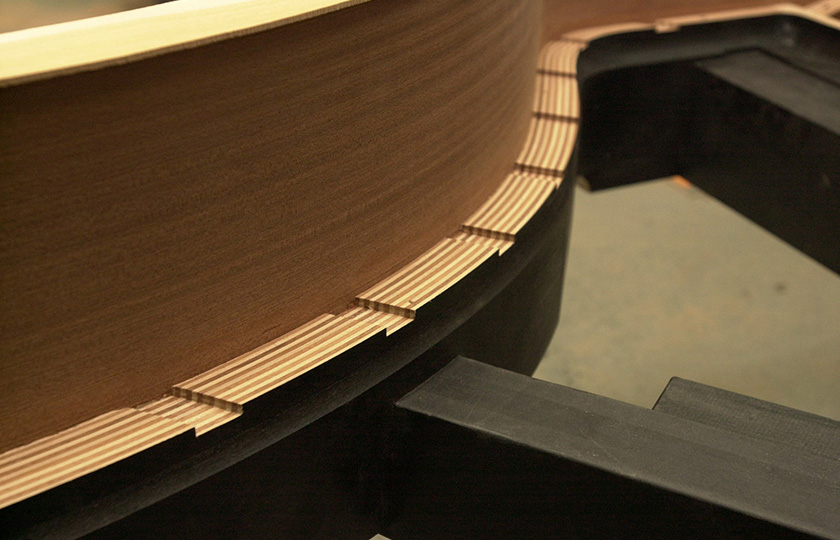

The inner rim of the piano is made in a similar way to the outer rim, with layers of veneer glued together to form a long piece which is then shaped in a press. Once this has been made, the straight beams which form the structural framework of the piano are fitted to the inner rim using dovetail joints. The surface is then planed to give a flat and smooth finish. The soundboard will later rest on this inner rim, which is milled to accommodate it.

The top of the soundboard has a crown (a slight dome) that arches upward toward the strings, and the top surface of the inner rim is cut to match its slope angle. In addition, several reinforcing ribs are glued to the underside of the soundboard, and slots are milled into the inner rim where these ribs will fit. Finally, the outer rim, which has been seasoned at a specific temperature and humidity, is joined with the inner rim into a single unit using high-frequency induction heating.

Finishing

The finish is applied robotically to ensure it is smooth and even. First, an undercoat is sprayed on and kept warm so that it dries and hardens quickly. The final topcoat is applied in the form of an extremely fine mist, followed by a polishing process that results in an attractive, beautifully finished surface.