The automatic key pressing machine is once again used after the piano has been seasoned, to prepare the piano action for regulation. This involves fine adjustments to the movement of the keyboard and action, ensuring that the instrument responds accurately to the pianist's touch.

The height of the keys and key drop need to be readjusted and the action regulated so that it plays evenly across the range. There are more than 10 adjustments for each key, and so a total of over a thousand separate adjustments must be made.

After installing the three legs and pedal lyre the instrument is fine tuned. On the notes where there are three strings, the middle string is tuned first with a "mute" inserted to silence the strings on either side. The right and left strings are then tuned based on the pitch of the middle string.

Here, a senior piano technician with many years of experience takes charge, and a final action regulation is carried out. Yamaha insists that the closer a piano gets to completion, the greater the requirement for a master piano technician to perform the adjustments.

Voicing

After the piano has been tuned it must be voiced as the raw hammers are very hard, giving the instrument a brittle and metallic sound. Voicing is the adjustment of the hardness and resiliency of the hammer felts to alter the tone and balance the notes. Specifically, in a process called filing, sandpaper is used to smooth the surface of the hammer felt and remove irregular fuzzing, to soften the felt when it has become too compressed, and to re-shape the hammer head. For notes that are strung with two or three strings, the hammer is shaped so that it strikes each string in the same way.

The main part of the voicing process is the pricking of the hammer felt to remove unwanted noise, increase flexibility, and help it produce the core sound. Knowing where to loosen up the felt and by how much requires the kind of expertise that only highly experienced technicians possess.

The finished article!

When the final voicing has been completed the piano is given one last inspection to check that the action and keyboard complement each other as expected and that there are no blemishes on the finish. The music desk is then installed, and the piano manufacturing process has been completed.

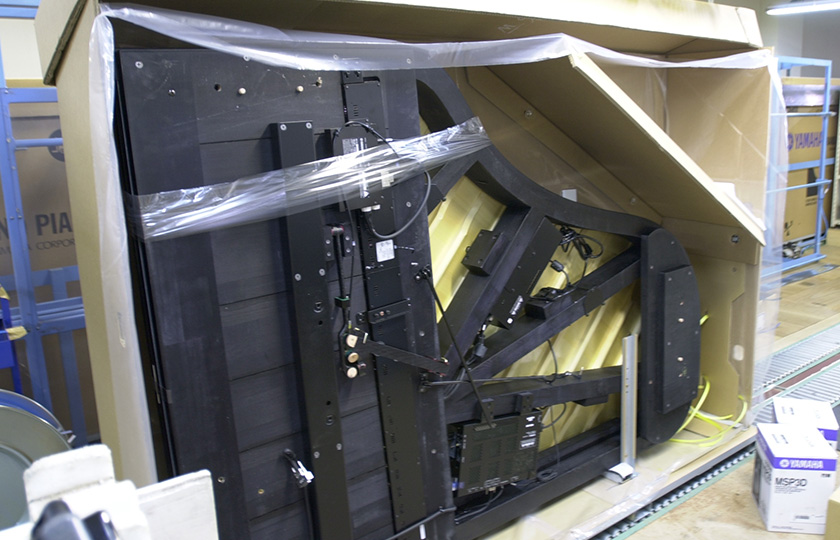

Pianos destined for customers in Japan are wrapped in heavy padded blankets, while instruments for overseas customers (which are shipped by ocean freight) are wrapped in moisture-proof plastic film and sealed in vinyl. The piano, along with its legs and pedal lyre are packed into a thick carton constructed of wood and corrugated cardboard and secured with a special bolt.